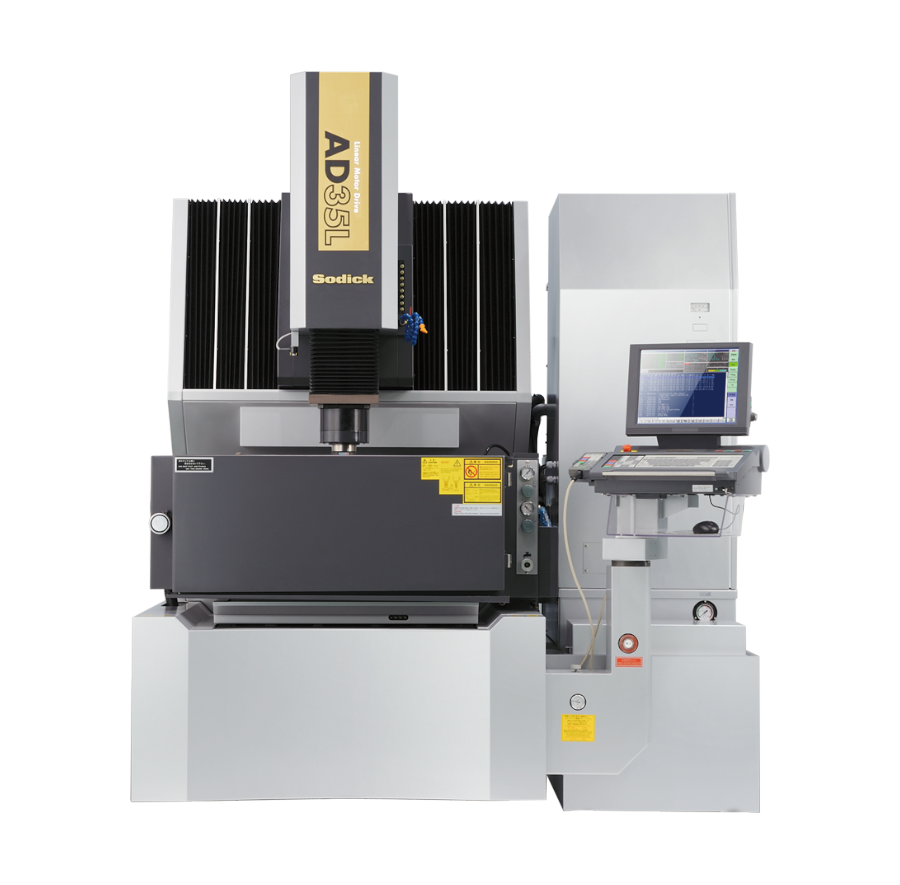

Screw-less Drive + Highly Rigid Construction

The screw-less drive, which uses a linear motor and linear scale, is the ideal drive method which maintains high-speed and high response performance semi-permanently. In addition, the AD35L employs the latest technology in highly rigid construction.

New NC Unit with “TMM3” Discharge Power Supply

The AD35L features Sodick’s latest “LN” NC unit equipped with the new “TMM3” discharge power supply, capable of high-speed, high precision and high-efficiency machining. It is equipped with “LN Professional”, automatic programming function, as standard.

Arc-less & High-Quality Surface Finish

The new “Arc-less” electrical discharge system features further improved in machining performance and ensures great reduction in machining time. Equipped with “SVC” circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with greater ease.

- 10 year warranty on positioning accuracy

- LN Professional

- Linear motor cooling unit

- Linear scales (X, Y, Z axis)

- Remote controller

- USB port

- Shuttle ATC

- SEC-10 (C-axis)

- SGF Plus Circuit

- 15″ TFT touch screen display

- Dielectric cooling unit

- Automatic voltage regulator

- Paper filter (2)

- Fire extinguisher

- Mouse

- LAN connection

- Tool kit

- Work light

Specification

| Work Table Size (W x D) [mm] | 600 x 400 (ceramic) |

|---|---|

| Work Tank Inner Dimensions (W x D x H) [mm] | 975 x 555 x 350 |

| Work Tank Fluid Level (Min to Max) [mm] | 170 – 300 |

| X Axis Travel [mm] | 350 |

| Y Axis Travel [mm] | 250 |

| Z Axis Travel [mm] | 270 |

| Max Weight of Electrode [kg] | 50 |

| Max Workpiece Weight [kg] | 550 |

| Machine Tool Dimensions (W x D x H) [mm] | 1895 x 1955 x 2350 (Includes Power Supply and Dielectric Tank) |

| Machine Tool Weight [kg] | 3200 (Includes a Power Supply and Dielectric Tank) |

| Dielectric Tank Capacity (Initial dielectric fluid supply amount [L] | 400 |

Japan

Japan