Non-Operating” hours greatly reduced, contributing to a higher “Operating Rate” the key to productivity.

Improves operating ratio of Metal 3D Printing

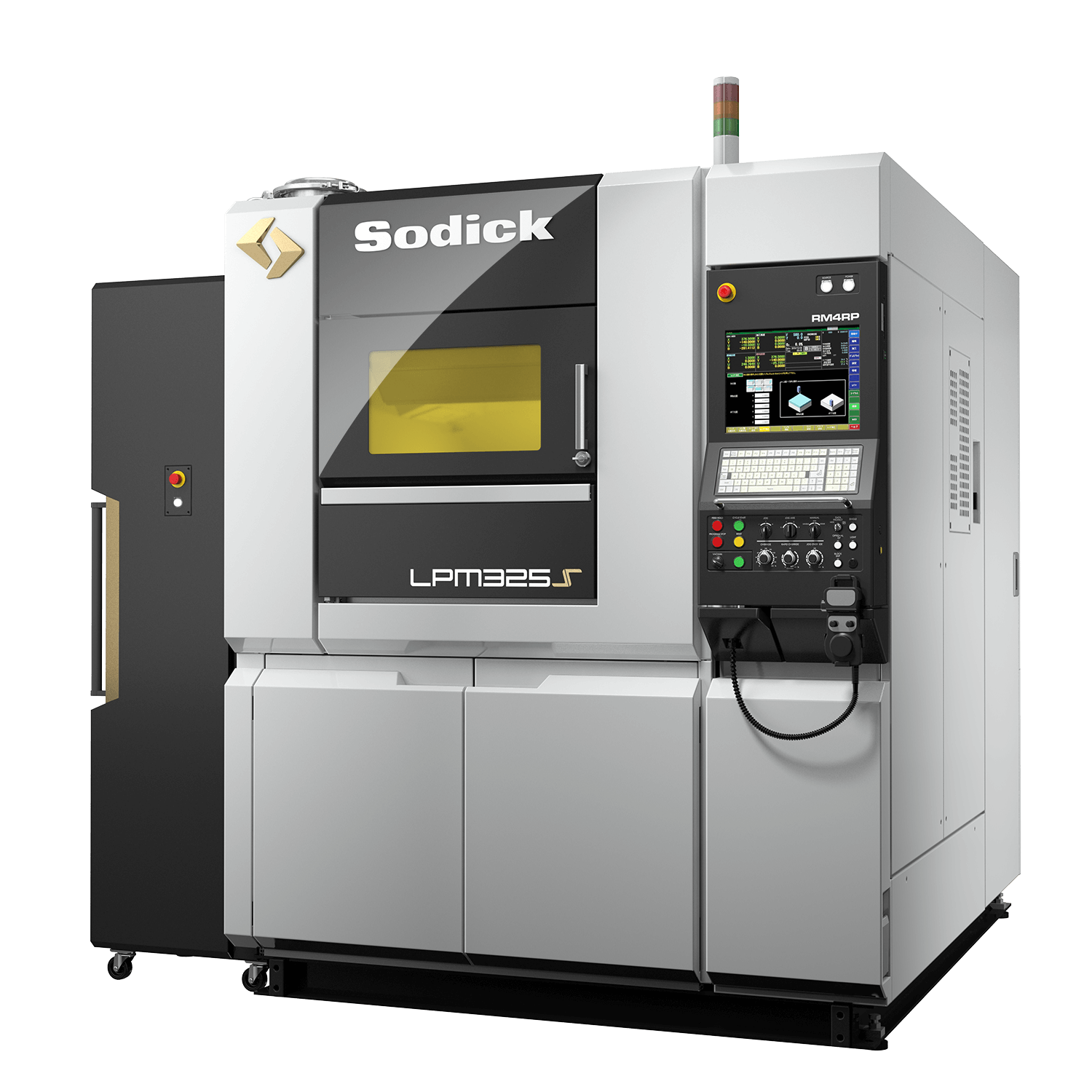

LPM325S is a Metal 3D Printer that performs additive laser 3D printing by melting and solidifying metal powder, as well as subtractive reference surface cutting of the workpiece by a single machine, greatly reducing the “non-operating” hours used for powder exchange and maintenance work and contributes to improvement in the “operating ratio” essential for productivity.

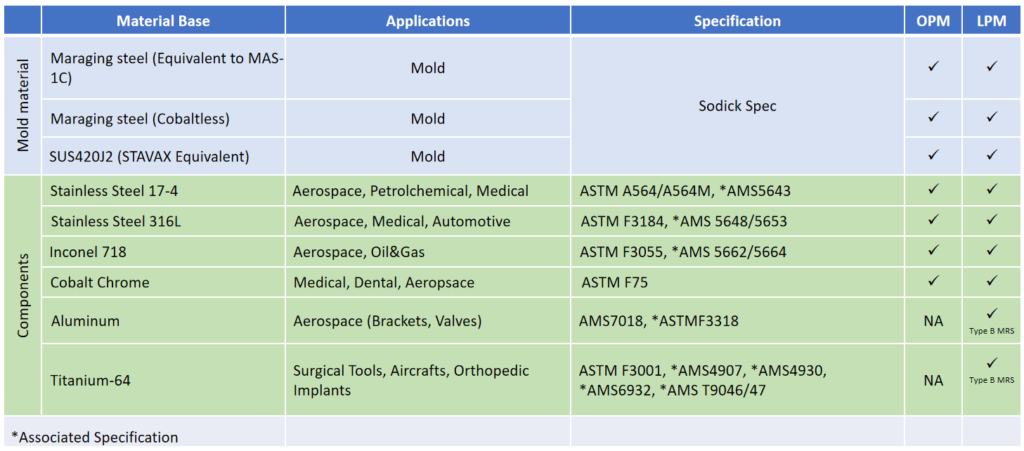

Enables various metal-powder to be used with one single machine

Standardly equipped with an original MRS (Material Recycle System unit which automatically supplies, recovers, and sieves the powder). Only a simple powder exchange work is necessary for switching various types of metal-powder.

(* Metal powders such as Steel, SUS, Aluminum and Titanium can be used)

Prevents printing error beforehand and capable of ultra-high-speed printing (Optional)

Equipped with a “Monitoring (Optional)” function, which constantly keeps track of various elements of the machine using advanced sensing technology to manage and prevent printing error before it happens. Also, can be equipped with the “Dual Laser (Optional)” which enables 2 times more printing speed capability (compared to Sodick’s previous model).

Specification

| Max Print Size (WxDxH) (mm) | 250 x 250 x 250 |

|---|---|

| Print Chamber Inner Dimension (WxD) (mm) | 314 x 386 |

| Table Dimensions (mm) | 278 x 250 |

| Max Load Weight (kg) | 120 |

| Distance from Floor ro Table Top Surface (mm) | 1020 |

| Initial Powder supply weight (Maraging Steel) (kg) | Max 100 |

| Machine Dimensions (mm) | 2160 x 2235 x 2240 |

| Machine Weight (kg) | 3500 x 3400 |

| Laser Method | Yb Fiber Laser |

| Laser Wavelength (nm) | 1070nm |

| Max Laser output | 500W |

| Laser scanning method | Galvano Method |

| Controlled Axes | 4 axes (X,Y,U,B) |

| Number of simultaneously controlled axes | Max. 2 Axes |

| Min.input unit (µm) | 0.1 |

| Min. Travel unit (µm) | 0.1 |

| Installed Software | MK50 |

Japan

Japan