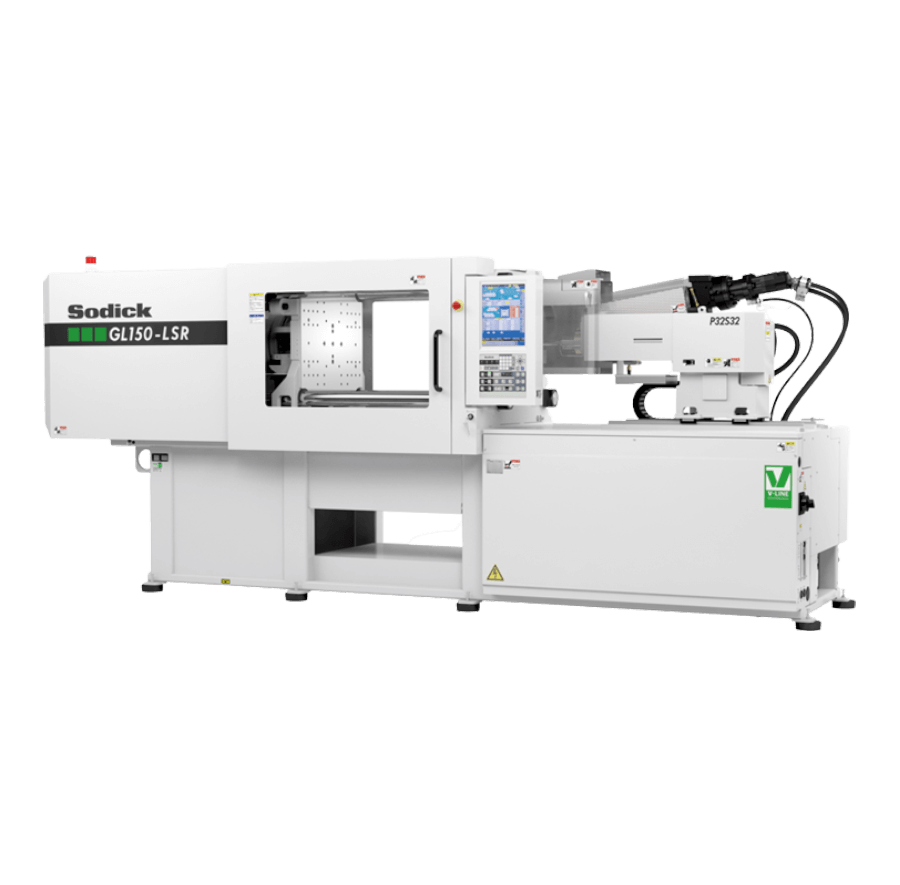

Broadly expands the range of the precision molding items field, including precision, electronics, optics, and medical instruments V-LINE® high response injection model

Stable molding by V–LINE®

Equipped with the unique V-LINE® which realizes accurate plastic injection with high repeatability. Fills the mold with a constant amount of resin during injection without backflow, by an accurate weighing mechanism and simple & rational backflow prevention mechanism.

Equipped with LIM dedicated unit

The V-LINE® is designed only for thermosetting, and supports each of the thermosetting resins from super-low viscosity to high viscosity. The resin flow path of each part is designed shorter so that it can be disassembled more easily, which provides excellent maintainability.

Electric hybrid direct pressure mold clamping

Combined with an open/close mold clamping mechanism that realizes accurate position control by an electronic system, and a mold clamping mechanism that performs constant mold clamping by a hydraulic system. Particularly, since the mold clamping force is distributed uniformly by a hydraulic cylinder, the mold is clamped uniformly which realizes high precision molding.

Specification

| Clamping System | Locking Direct Pressure |

|---|---|

| Max. Clamping Force (kN) | 1472 |

| Tie Bar Distance WxL (mm) | 560 x 520 |

| Platen Dimensions WxL (mm) | 720×680 |

| Open Daylight (Min. Mold Thickness + Max Stroke) (mm) | 900 |

| Min Mold Thickness / Max Mmold Thickness (mm) | 250 / 600 |

| Platicization and Injection System | Feed Screw & Plunger |

| Screw Diameter (mm) | 28 | 40 |

| Plunger Diameter (mm) | 28 | 32 | 40 |

| Max Injection Pressure (Mpa) | 240 | 220 | 210 |

| Theoretical Injection Volume (cm³) | 83 | 108 | 251 |

| Injection Rate (cm³/s) | 123 | 161 | 251 |

| Max Injection Speed (mm/s) | 200 |

| Plasticating Capacity (Kg/h) | “ |

| Machine Dimension (mm) | 4400 x 1378 x 1878 |

| Machine Weight (Kg) | 5000 | 5100 |

| Mold Clamping Force Classification | “ |

| Drive System | Electric Hybrid |

Japan

Japan