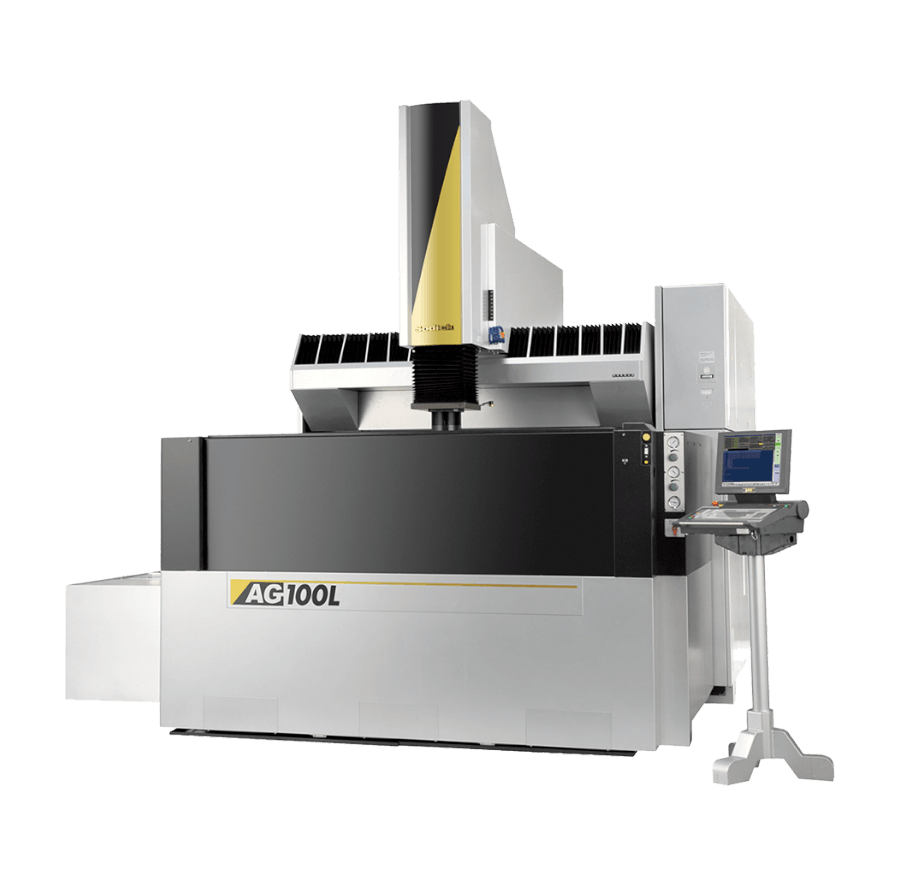

3-axis Linear Motor Drive & Highly Rigid Machine Structure

The adoption of the independently developed linear motor demonstrates high-speed and dynamic response servo performance even with its large size. The unique Y-axis structure demonstrates high-speed and stable performance even with the horizontal servo and second cut of the 3-axes.

Stable Electrical Discharge System “Arc-less Plus”

The adoption of “Arc-less Plus” increases the speed further, suppresses electrode wear to the utmost, and realizes various machining surface qualities from satin to mirror surfaces.

Maximum Machining Range in the Series

The optimized machine design based on the C-type column specification of “AG100L,” supports larger sized workpieces with reduced installation area. Adoption of the double structure slide method for the Y-axis reduced the moving weight while extending the strokes of the machining axes, which enables high-speed machining.

- 10 year warranty on positioning accuracy

- Linear Motor (X/Y/Z axis)

- Absolute Linear scale (X/Y/Z axis)

- Ceramic components

- Linear motor cooling unit

- Dielectric fluid cooling unit

- SVC circuit

- “SGF2” Nano-Wear Discharge Unit

- TMM3 generator

- Improved Ease of Operation

- Remote controller

- LN Professional software for optimum condition search

- Clamping chuck

- LAN interface

- USB port

- 15″ TFT Screen

- Work light

Specification

| Work Table Size (W x D) [mm] | 2500 x 1550 (ceramic) |

|---|---|

| Work Tank Inner Dimensions (W x D x H) [mm] | 3000 x 1800 x 1000 |

| Work Tank Fluid Level (Min to Max) [mm] | 520 – 950 |

| X Axis Travel [mm] | 2000 |

| Y Axis Travel [mm] | 1200 |

| Z Axis Travel [mm] | 800 |

| Max Weight of Electrode [kg] | 100 |

| Max Workpiece Weight [kg] | 10,000 |

| Machine Tool Dimensions (W x D x H) [mm] | 4770 x 5220 x 4605 (Includes a power supply and service tank) |

| Machine Tool Weight [kg] | 19,000 |

| Dielectric Tank Capacity (Initial dielectric fluid supply amount [L] | 7000 |

Japan

Japan