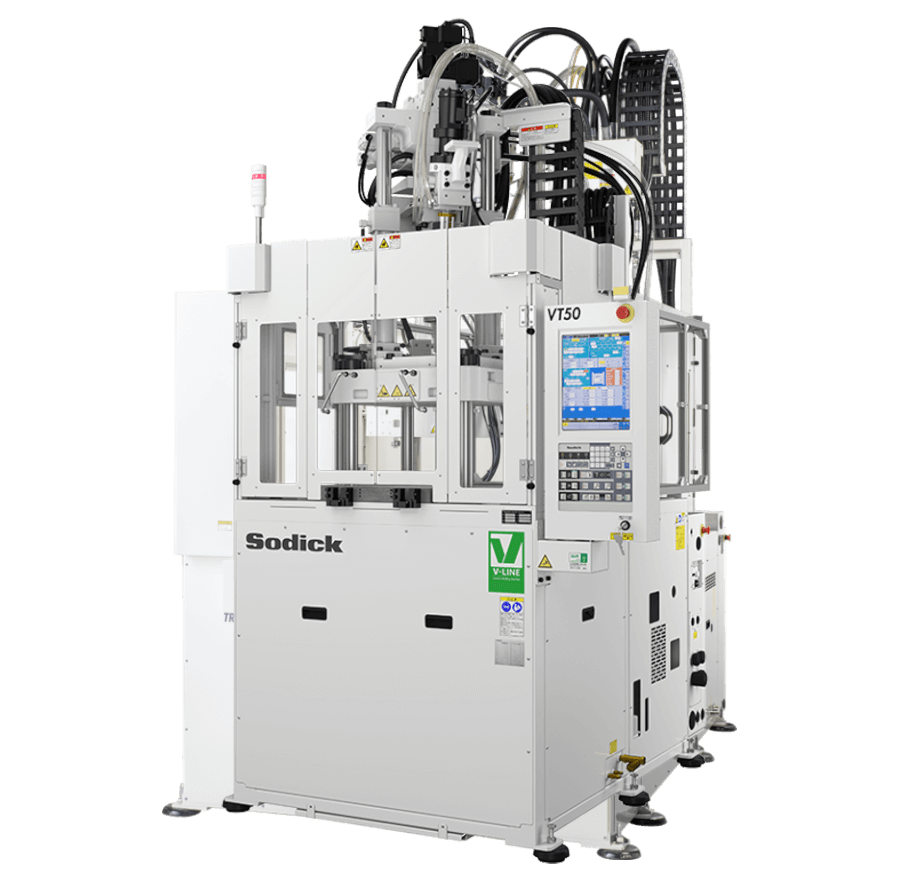

Realizes High Yields of Insert Molding V-LINE® and locking direct pressure method. The rotary table which accurately stops in position expands the prospects of automation.

Stable Molding Enabled by V-LINE®

The V-LINE® consists of a plasticization and injection unit which enables stable measurement and injection, realized by eliminating the destabilizing factors during the plasticization measurement and injection, by separating the plasticization and injection. Sodick’s original control technology enables plasticization and injection control at optimal timing.

Locking Direct-pressure Mold Clamping

The well-balanced arrangement of the three hydraulic cylinders for mold opening and closing with the movable platen connected to tie-bars realizes excellent straightness, and the locking direct pressure generates a high mold clamping force with uniform repeatability. The electric servo driven rotary table realizes excellent stop position accuracy and high speed.

Space-saving and Improved Workability

The height of the table was made lower than the conventional machine in order to improve the workability.

The V-LINE® with a shorter mechanism even made the overall height of the machine lower which realized space savings.

Injection & plasticization unit

The injection and plasticization unit succeeded the V-LINE® which realized stable and high accuracy molding. A high-speed and high-pressure specification and dynamic response specification equipped with the super-dynamic response LDDV*injection valve can also be selected.

*LDDV = Linear Direct Double Valve

Specification

| Clamping System |

Double Toggle |

|---|---|

| Max. Clamping Force (kN) | 490 |

| Tie Bar Distance WxL (mm) | 420 x 360 |

| Platen Dimensions WxL (mm) | 610 x 550 |

| Open Daylight (Min. Mold Thickness + Max Stroke) (mm) | 600 |

| Min Mold Thickness / Max Mmold Thickness (mm) | 250 / 350 |

| Platicization and Injection System |

Screw Pre-plasticizing |

| Screw Diameter (mm) | 18 | 22 | 28 |

| Plunger Diameter (mm) | 16 | 22 | 28 |

| Max Injection Pressure (Mpa) | 262 | 256 | 252 |

| Theoretical Injection Volume (cm³) | 14 | 27 | 83 |

| Injection Rate (cm³/s) | 80 | 114 | 123 |

| Max Injection Speed (mm/s) | 400 | 300 | 200 |

| Plasticating Capacity (Kg/h) | 7 | 14 | 30 |

| Machine Dimension (mm) | 1934 x 1643 x 3274 | 3502 |

| Machine Weight (Kg) | 3000 | 3150 |

| Mold Clamping Force Classification | AC Servo Motor Control |

Japan

Japan