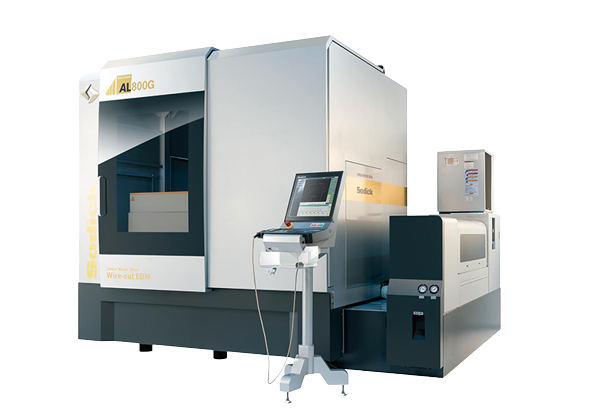

Achieving the superlative performance with in-house developed core technologies. Advanced Smart Pulse & Advanced Smart Linear.

4-Axis (XYUV) Linear Motor Drive

High-performance linear motors developed and manufactured by Sodick are adopted for the four XYUV axes. They can maintain accurate axis

movement with no backlash semi-permanently, something that is impossible with conventional ball screw drive methods. The high response

and high tracking performance that are features of linear motors achieve accurate position control and excellent discharge characteristics

during machining.

High Rigidity Construction and Precision Thermal Compensation System

The AL800P adopts a high rigidity construction supported by the ultra-precise roller guide as well as featuring a machining fluid circulation system for major structural components. In addition, a newly developed high-precision thermal compensation system and automatic temperature control by a high-performance inverter cooler minimize the thermal displacement during high-precision machining of large

workpieces.

Latest “SPW Power Supply” NC Unit and New Machining Circuits

A variety of the latest technologies for highspeed, high-precision, and high-quality machining, such as Digital-PIKA-W Plus, TMP control II, Barrel-free Effect Control II, new tension servo function, and automatic float control are installed as standard to achieve stable high-efficiency machining with the minimum number of cuts. The horizontal 19-inch touch panel screen offers advanced operability and functionality.

Large and Thick Workpiece Machining

The AL800G supports a 500mm workpiece thickness machining standard. It equipped with the automatic vertically sliding door, the “O-shape” work-stand, and

ceramics made stand-bases. The high-speed automatic wire threading unit (FJ-AWT)

and the built-in 20kg wire feeder enables unattended high speed and high precision machining.

Specification

| Dimensions in Machining Tank (WxD) (mm) | 1500×1040 |

|---|---|

| X Axis Travel (mm) | 800 |

| Y Axis Travel (mm) | 600 |

| Z Axis Travel (mm) | 500 |

| U-Axis x V Axis Travel (mm) | 200 x 200 |

| Max Taper Angle | ±25° |

| Max Workpiece Size (WxDxH) (mm) | 1250 x 1020 x 500 |

| Max Workpiece Weight (kg) | 3000 |

| Wire Electrode Diameter (mm) | Ø0.10 – Ø0.30 |

| Wire Tension | 3-23N |

| Maximum Wire Feed rate | 420mm/sec |

| Distance from Floor to Table Top (mm) | 995 |

| Machine Dimensions (WxDxH) (mm) | 3395x3640x2780 |

| Machine Wieght (Including P/S) (kg) | 6000 |

Japan

Japan