Linear Motor Drive System

Linear motor drive system is the most ideal mechanism which semi-permanently sustains high-speed axis-movements and instantaneous response. With 10-years of history providing linear motor-driven machines.

New Generator

The 5th generation electrical discharge technology has adopted the “Perfect Active Control,” enabling simultaneous control of high-speed electrical discharge and axis-movements by using serial communication technology of 1Gbit/sec.

Arc-less & High-Quality Surface Finish

The new “Arc-less” electrical discharge system features further improved machining performance and ensures a greater reduction in machining time. Equipped with “SVC” circuit as standard, high-quality surface finishing, satin surface, and mirror surface can be achieved with great ease.

- 10 year warranty on positioning accuracy

- Linear Motor (X/Y/Z axis)

- Absolute Linear scale (X/Y/Z axis)

- Ceramic components

- Linear motor cooling unit

- Dielectric fluid cooling unit

- SVC circuit

- “SGF2” Nano-Wear Discharge Unit

- TMM3 generator

- Improved Ease of Operation

- Remote controller

- LN Professional software for optimum condition search

- Clamping chuck

- LAN interface

- USB port

- 15″ TFT Screen

- Work light

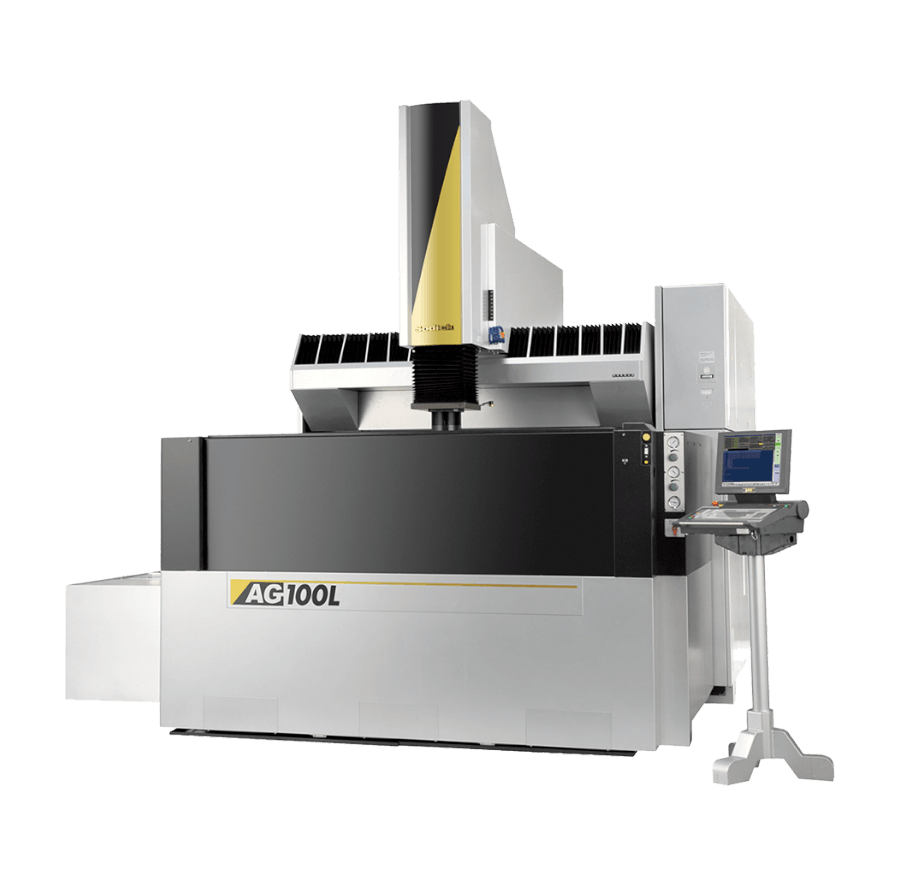

Specification

| Work Table Size (W x D) [mm] | 1600 x 1000 (ceramic) |

|---|---|

| Work Tank Inner Dimensions (W x D x H) [mm] | 2100 × 1250 × 650 |

| Work Tank Fluid Level (Min to Max) [mm] | 325 – 600 |

| X Axis Travel [mm] | 1200 |

| Y Axis Travel [mm] | 650 |

| Z Axis Travel [mm] | 500 |

| Max Weight of Electrode [kg] | 100 |

| Max Workpiece Weight [kg] | 5000 |

| Machine Tool Dimensions (W x D x H) [mm] | 3820 × 4200 × 3340 (Including CNC) |

| Machine Tool Weight [kg] | 12500 |

| Dielectric Tank Capacity (Initial dielectric fluid supply amount [L] | 2770 |

Japan

Japan